1 What is an overdrive and why do they exist?

In the late 1950’s through to the 1970’s there was an explosion of Motorway and dual carriageway trunk road building in Britain that made the previous main A-routes seem like slow country lanes. The result saw cars able to cruise at much higher speeds for longer periods which created much more stress on engines that were low geared to suit the previous types of road. Cars now needed longer gearing to reduce that stress but simply raising the rear axle ratio wasn’t always ideal as it lengthened every gear and smaller less powerful engines of the period would suffer stunted acceleration and also potentially create hill start problems.

What was needed was an extra gear on top of the existing top gear, an overdrive ratio. Adding an extra gear into existing gearboxes was usually impossible so that would dictate a new gearbox design that would be excessively costly. So the easy solution for motor manufacturers was to add the extra gear as a compact self-contained unit after the existing gearbox, something called an Overdrive.

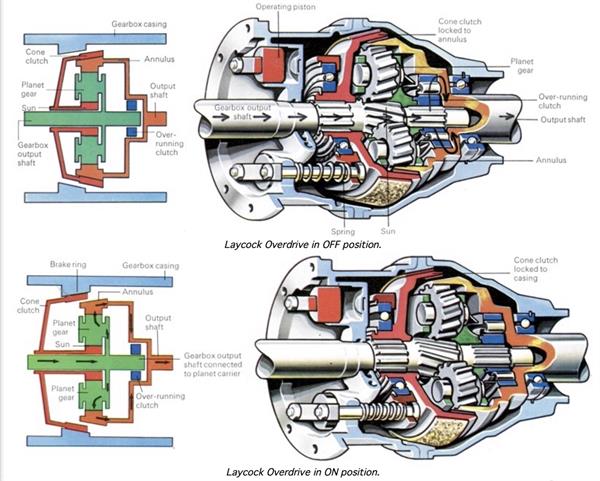

An Overdrive offers two different gear ratios through an epicyclic gear. One is known as Direct Drive (Overdrive not switched in), is where the rotational speed on the input into the front of the Overdrive comes out at the back at the same speed. The second is when the Overdrive is engaged and now the internal gearing is operating and so the rotational speed on the output side is greater than the input side speed. This reduces the engine rpm for any given road speed.

2 Who made them?

The invention of the Overdrive is credited to Edgar de Normanville in the late 1940’s and it was manufactured by Laycock Engineering in Sheffield, hence the common sales title of Laycock de Normanville Overdrive. It must be said though that other manufacturers also made overdrive units. Laycock Engineering was originally established back in 1884 and went through a range of different owners before it was closed in the mid-1970’s.

Laycock Overdrive Factory, Sheffield.

Laycock Overdrive Factory, Sheffield.

3 Where is it fitted and how does it work?

An overdrive unit is mounted between the gearbox and rear axle on a rear wheel drive vehicle or before the drive from the gearbox enters the transfer box on a four wheel drive vehicle. The main internal components are the epicyclic gear, a clutch, oil pump, operating pistons and a solenoid valve.

LH - type Overdrive cutout showing clutch sliding member and epicyclic assembly.

LH - type Overdrive cutout showing clutch sliding member and epicyclic assembly.

MG and many other applications have the overdrive bolted to the rear of a modified original gearbox casing with the third motion (output) shaft modified so that it engaged directly into the overdrive and also has a cam that drives the Overdrive’s internal oil pump, which sees the oil pump generate seriously high pressure that will on MGs be over 400psi. In Direct drive (remember, overdrive not switched in), the internal clutch is not engaged so the whole internal gear assembly rotates so acting as if the drive from the gearbox to axle is a solid shaft.

The image above shows an original MGB gearbox casing (green arrow) has been altered to provide a round mounting flange for the Overdrive to fit against, whilst the gearbox mainshaft (Red arrow) is modified to engage inside the Overdrive and also provide a cam to operate the Overdrive oil pump.

The image above shows an original MGB gearbox casing (green arrow) has been altered to provide a round mounting flange for the Overdrive to fit against, whilst the gearbox mainshaft (Red arrow) is modified to engage inside the Overdrive and also provide a cam to operate the Overdrive oil pump.

When the driver engages Overdrive a solenoid operates an internal valve that redirects oil pressure into a pair of hydraulic pistons that push the clutch into engagement with the brake ring on the inside of the Overdrive casing. This stops the main assembly from turning and engages the sun and planet gears now altering the gearing with a ratio of around 0.8 to one or approximately reduces the engines speed by approximately 25%. This position is maintained all the time that the oil pressure is present and allowed to feed the pistons. Switching the solenoid ‘off’ diverts the oil pressure from feeding the pistons, when internal return springs return the Overdrive to direct drive.

Pictured above we can see the front face of an Overdrive unit that bolts up to the back of the MGB gearbox. The yellow arrow is pointing to the Overdrive oil pump shaft and its return spring whilst the red arrows point to the two internal operating pistons.

Pictured above we can see the front face of an Overdrive unit that bolts up to the back of the MGB gearbox. The yellow arrow is pointing to the Overdrive oil pump shaft and its return spring whilst the red arrows point to the two internal operating pistons.

Over the years there has been variable comments on how best to use an overdrive. MGs guidance is simple by holding a steady throttle position and switching the overdrive in or out. It specifically states that it is not necessary to depress the clutch pedal as some owners prefer to do. Normal Overdrive operation when engaging usually sees a one to two second delay from switch operation to engagement, but switching out should be instant.

4 What MG models are fitted with it?

MG was relatively late to the Overdrive party and did not provide this option until early 1963 with the MGB using the D - type Overdrive. This was superseded by the LH series Overdrive in late 1967 when the new all-synchromesh gearbox was introduced with the Mk2 MGB and this remained an option until June 1976 when it became standard equipment for UK market cars, although it had been the preferred option for most buyers for several years prior. The MGC introduced at the same time as the Mk2 MGB (1968) also had the LH as an extra cost option, whilst the 1973 MGB GT V8 used an uprated version of the same all-synchromesh gearbox with the LH Overdrive as standard.

D - type overdrives were fitted to 3 synchromesh MGBs from 1963-67

D - type overdrives were fitted to 3 synchromesh MGBs from 1963-67

LH - type overdrives were fitted to MGB/Cs & GT V8 from 1968-80.

LH - type overdrives were fitted to MGB/Cs & GT V8 from 1968-80.

Identifying your Overdrive

D - type overdrive fitted to 3 synchromesh MGBs from 1963-67 - 22H210E

LH - type overdrive fitted to MGB/Cs & GT V8 from 1968-80 - 22H1283E / 22B397E / 22B687E / DAM1362E

LH - type overdrive fitted to MGB/Cs & GT V8 from 1968-80 - 22H1283E / 22B397E / 22B687E / DAM1362E

Note LH - type Overdrives of which there were four specifications fitted for MGB/C derivatives can be easily identified by their ID plate:

- Black label signifies chrome bumper (1968 to 1974) LH MGB overdrive - 22H1283E

- Blue label signifies rubber bumper (1975 to 1980) LH MGB overdrive - DAM1362E

- Red label signifies MGB GT V8 LH overdrive - 22B687E

- Green label signifies MGC LH overdrive - 22B397E

An LH Overdrive viewed from below, note the printed ID plate held on by four screws that also secures the internal solenoid.

An LH Overdrive viewed from below, note the printed ID plate held on by four screws that also secures the internal solenoid.

MGBs fitted with OD saw it operating on both third and top gears apart from US market models from February 1977 when it was allowed to operate only on top gear. MGCs with Overdrive had it operate on third and top whilst the V8 initially had it on third and top but that was soon restricted to just top gear.

5 How reliable are they? Common faults, troubleshooting and improvements.

Overdrives that are given regular servicing and use correct lubricants are very reliable and also very tolerant of dealing with lightly enhanced engine power, except perhaps the V8 when larger capacity engines with huge torque increases are fitted. Eventually, with high mileage, they will wear and need specialist reconditioning, for which MGOC Spares offers reliable serviced reconditioned units on exchange.

Most common faults, which might be addressed by the vehicle owner centre around the electrical aspects of the Overdrive. Being hidden in the depths of the transmission tunnel where oil leaks and general dirt combine to make a mess; this often creates issues with wiring connections. The D - Type Overdrive has a slightly more complex wiring set up where the ignition controlled power supply from the manual dash switch travels to a vacuum switch that is located between heater and left bonnet hinge in the engine bay; that is if it hasn’t been removed by a previous owner.

Above is an image of a 3-sychromesh (1963-67) overdrive vacuum switch located on the left hand side bulk head, adjacent to the heater box assembly.

Above is an image of a 3-sychromesh (1963-67) overdrive vacuum switch located on the left hand side bulk head, adjacent to the heater box assembly.

If present and working properly the vac switch only allows power to pass when there is a light throttle opening with high inlet manifold vacuum that is intended to soften the torque loading during Overdrive engagement. When power is allowed to pass the vac switch it reaches the inhibitor switch on the gearbox remote housing and only if the gear lever is in third or top position will it allow that power to pass onto the overdrive solenoid. Operation of the LH Overdrive is slightly simpler in that the vacuum switch was deleted by MG, but the rest of the connections to the solenoid and inhibiter switch remain the same.

The driver's switch controlling the Overdrive changed over the years. MGBs to 1974 and all MGCs had the dash mounted overdrive switch to the right of the fuel gauge (part number BHA4513). Early MGBs had a standard short stem toggle switch but this was changed in April 1965 for the distinctive cranked (Shepherds Crook) type. The V8 from its introduction in 1973 had Overdrive switching incorporated into the wiper stalk (part number BHA5251) and this was adopted for the four cylinder cars in Sept 1974 as one of the many modifications with the ‘rubber’ bumper models. This lasted until September 1976 when the 1977 model year cars arrived, (five dials in the dash plus ‘deck chair’ striped seat material); the Overdrive switch now moved to the top of the gear knob (part number 520999A), Triumph style.

Dash-mounted toggle switch seen on early MGBs (up to 1974) and all MGCs - BHA4513

MGB GT V8 and MGB 1974-76 Overdrive switch on the stalk in the On position. BHA5251

Overdrive switch on the top of the gear knob as seen on MGBs from 1976 on. 520999A

Probably the biggest potential problem area with the standard Overdrive wiring is the fact that the ignition controlled power supply to the Overdrive switch is NOT FUSE PROTECTED and especially on the 1977 and later model years cars with the Triumph style gear knob mounted Overdrive switch means that any short will see wiring burn out and often take many other wires with it. The issue is much worse with these later cars as the power fed wiring comes down the tunnel and has to do a 90 degree upwards turn to run up a frontal groove in the gear lever to enter the knob to connect to the switch. The second wire from the switch to the gearbox mounted inhibitor switch follows a similar reverse route.

The problem is very simply wiring fatigue as the wiring is subjected to some bending every time the gear lever is moved. Wires do break firstly inside the plastic insulation but sometimes also breaking the insulation so now if the power feed wire is broken when the ignition is on this live wire is floating about on top of the gearbox ready to short out! It’s very simple to add a 5 or 10 amp line fuse to the power feed side and is highly recommended. If your Overdrive or switch harness is damaged due to wear, replacements are available as follows:

Other electrical issues are usually poor connections where dirt or loose connectors are not making contact. When an overdrive fails to engage firstly do a voltage check into the solenoid wire on the Overdrive and check if there is power when the ignition is on, gear lever in fourth and the Overdrive switch engaged. That should show 12v and be within 0.2v of the battery voltage; any greater loss points to poor connections or possible wiring fault. Also check the operation of the solenoid as with the engine not running in a quiet environment you should be able to hear and with finger on the solenoid housing feel movement. The solenoid is one of the few parts that can be changed without a need to remove the engine gearbox. MGOC Spares stocks these under part number 10002 for D - type and 37H1934 for LH - type Overdrives.

No solenoid voltage means checking the feed wire where it connects to the main wiring near the steering joint under the bonnet to check for 12v there and if present then expect the wiring or inhibitor switch to be the most likely source of the problem.

If all is well electrically then check the oil level in the gearbox where a low level needs to be corrected before driving to check if it now works. The next most common problem is lack of servicing and incorrect oil choice. The service schedule for the MGB is every two years or 24,000 miles with a drain and refill using normal 20W/50 engine oil for all models except the V8 that has changes in the Overdrive to cope with EP90 gear oil. Remember that these gearboxes are old design and have white and yellow metal parts inside that can be damaged by some very modern transmission oils. Whilst the service schedule was created at a time when the cars were seen in daily use this clearly hasn’t been the case for many years so the change time point can be reasonably extended to every four or five years, unless the miles clock up to the original 24,000 before that time elapses.

Related to oil choice is the volume of oil needed and also to be aware a single oil supply feeds both the gearbox and Overdrive. There are different quantities listed for the earlier three synchromesh and later All synchromesh gearboxes and both have extra volume when an Overdrive is fitted. Before mentioning the volumes I must point out a decades long error in relation to the three synchromesh gearbox and Overdrive that is listed at 5.3 pints but the error is that this has quoted for years in all manner of publications at 3.36 litres rather than the correct conversion to 3.01 litres. By comparison the All synchromesh gearbox and Overdrive uses 6 pints or 3.4 litres. If the oil level is allowed to drop significantly then the Overdrive may start to drop in and out or not engage due to there being insufficient oil to generate the required oil pressure. It follows that accurate final filling using the inbuilt dipstick on the chrome bumper cars or combined filler/level plug on Rubber bumper cars should be used.

If there is clutch slip indicated by engine RPMs changing with no change in road speed and it isn’t the main engine to gearbox clutch, or the overdrive drops into a free wheel when cruising or doesn’t want to drop out once engaged then often this is indicating an internal issue that if not solved by fresh oil and filter (D - type filters should be cleaned and reused | For LH see 37H1942) clean points to a need for specialist help or a rebuilt exchange Overdrive.

Fresh oil and a filter can work wonders!

Fresh oil and a filter can work wonders!

6 What is the situation with spare parts and what are the costs?

Obtaining rebuilt and guaranteed Overdrive units on exchange has always been the most popular and effective route to follow if the Overdrive is diagnosed with internal problems. As the Overdrive can’t be removed separately until the engine and gearbox are removed from the car carrying out ‘first aid’ type repairs are often short sighted as this is a component that you want to make sure is 100% functional to avoid the inconvenience/cost of engine and gearbox removal for a second time to fix something that could have been done first time.

However, there are many owners who enjoy and relish the job of stripping, cleaning and repairing mechanical items to get them back into full working order and an Overdrive is no exception. Fortunately here MGOC Spares caters for these owners with good spares availability, including filter sump gasket (37H1942) that should be part of regular servicing, a new solenoid should the coil winding fail (D type 10002 or LH type 37H1935 + seal kits 37H1934K), the inhibitor switch located on the gearbox (BAU1074) that is also the same part used for the reverse lamp switch, Overdrive loom (BL672, BL673, BL674), Overdrive switch harness for 1976 on late Rubber Bumper cars (153726), Overdrive switches (early dash mounted BHA4513, Stalk, BHA5251, Gear Lever 520999A), relined Overdrive clutch/sliding member (17H8017E or 37H3461E), most importantly, the OD rear oil seal (D type 7H8325 or LH type NKC39) noting that it is not uncommon for the seal to be damaged giving rise to an oil leak, through prop shaft vibration or failure to support the gearbox and axle adequately upon install.

Experience of Overdrive issues means we should observe the significant differential in operating pressures between the high and low pressure environments within the Overdrive main ring and the risk of incursion by over exuberant tightening of main ring to gearbox studs during install which can see a leak arise which is often mistaken for a weeping relief plug. Sometimes this can be remedied in situ by fitting 8 x ¼” Copper washers (GHF361) to seal the stud.

7 Can an Overdrive be retro fitted into cars not originally fitted with one?

The answer is technically yes, but today is practically very much more difficult, simply because the Overdrive and non-Overdrive gearboxes are physically different, so to convert a non-Overdrive car to one with Overdrive means that you have to firstly buy a second hand gearbox with Overdrive that is in a reconditionable condition that is going to be usually more than £250. Its unwise to fit a used second hand gearbox and overdrive unless you are super sure of its provenance, so then you need to add the cost of having both elements reconditioned that will be close to £1000 for the gearbox and another near £700 for the overdrive, and don’t forget to include a new propshaft that is likely needed for a pre-1968 car (see part number AHH7486).

8 Are there more modern alternatives to an overdrive?

Yes as whilst the costs of designing and making a five speed gearbox was often too much for the 1950’s to ‘70’s car makers the five speed gearbox has since become common place with fifth gear usually offering a higher ratio than fourth so 5th gear is effectively the same gearing as what the Overdrive delivers.

For many years the Ford Type 9 five speed gearbox has been available to be fitted into many MGs to provide a very effective alternative to an overdrive, and where there isn’t the space for an overdrive such as the Midget, T series, Z saloons and MGA the compact and efficient Type 9 has offered a very effective route to overdrive cruising and more effective gearing and efficiency. In more recent years the party has been joined by a Mazda MX5 five speed conversion offering the same significant benefits.

G885 - MGB V8 5 Speed Mazda Gearbox

G828 - MGB 5 Speed Gearbox Conversion

The main difference being that the Ford Type 9 gearbox has not been made for many years and so most conversions rely on a rebuilt second hand gearbox whilst the Mazda gearbox is still being made new and the conversion has Mazda’s blessing. These conversions are quite simply superb offering a significant improvement in change quality, gear ratios and absorbing less engine power to provide a clear advantage over the original before you consider the fifth gear and what it offers. Interestingly inside the car the conversions retain the general look of the original MG set up with the lever emerging from the same position and following the same shape. The downside is the cost as this will usually exceed £4000 before fitting.

MGOC Spares offers a full range of 5-speed gearbox conversions available for MGA, MGB, MGB V8, MGCs and Midgets.

Who are MGOC Spares?

At MGOC Spares, we provide dedicated parts and accessories for classic MG vehicles, including the MGB, Midget, MGC and many more.

With thousands of products in stock, we are your one-stop shop for all your classic car needs. Our wealth of expertise means that you can trust us to find the right part for your classic MG vehicle – whatever it may be.

Need support finding the right parts for your MG? Contact us today, we're happy to help!